-

Call Us:+86-21-63353309

[email protected]

Call Us:+86-21-63353309

[email protected]

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Find Crusher Aggregate Equipment from CEDARAPIDS, KPI-JCI, and , and more, for sale in HILLSBORO, OREGON

Learn More

14/07/ · Safe and sound: Crusher safety. By Kevin Yanik | July 14, . A rock the size of a dining room table is plugged in the jaw crusher. After assessing the situation, a few people decide to wrap a chain around the rock and lift it out with a wheel loader. After securing the chain around the rock in the crushing chamber, a man still in the chamber

Learn More

05/06/ · Technidrive use WEG equipment to create innovative jaw crusher unblocking system. Technidrive were not only able to improve the efficiency and reliability of the motor, but also the efficiency and safety of the entire jaw crusher system. With more than 20 years’ experience in industrial drives, they used all their expertise to meet the

Learn More

22/03/2022 · The jaw crusher is mainly composed of a frame, a movable jaw assembly, a movable jaw, a fixed jaw, a triangular wheel, a flywheel, a bracket, a side guard, a discharge port adjusting device and a driving device. Because of its simple structure, easy manufacture, reliable operation and convenient maintenance, it has been widely used in crushing

Learn More

The Power of the Jaw Crusher While there are many different types of crushers to accomplish a variety of tasks, they generally fall within two types, impact crushers and compression crushers. This kind of irresponsible activity, from atop the operator's platform or on top of the crusher, is a serious breach of safety and could result in

Learn More

Improving jaw crusher safety 09 Jun | News According to the Health and Safety Executive's guidance for the safe operation and use of mobile jaw crushers, equipment operators may be subject to multiple risks including exposure to dust, noise, whole body vibration and being struck by objects ejected from the crusher.

Learn More

The crusher should be shut off and isolated before considering the use of bars and hand hammers. Careful consideration should be given to the risk of large pieces of feed material moving and

Learn More

Safety Regulation of Jaw Crusher author:dahua time:2019-11-19 Jaw crusher is the common used stone crusher machine in mining industry. It has the features of simple structure, stable

Learn More

movable jaw jc2540 jaw crusher: 00902k: movable reg curve jaw 2640 jaw c: 0264000126: moveable jaw bellied: 0304205103: nib bolt: motaz1781: nut: 0546000150: nut for side liner bolt: mot002258: nut jawface wedge: j54ac223: nut m30 x 3.5 nyloc: mot002259: nut m36 x 4.0 nyloc: mot004224: nut plain m48 gr5:

Learn More

The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and pre-crushing of mediumhard, hard, brittle and tough materials. The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants.

Learn More

This system ensures very good power transmission from the drive unit to the crushing mechanism, making double-toggle jaw crushers ideal for crushing extremely durable materials. Another advantage is the high wear resistance due to the kinematics of the crusher. All Mining Technologies jaw crusher features and benefits at a glance!

Learn More

20/07/2022 · It is inevitable for crusher to get wear because of long-time crushing work, and all you can do is try your best to maximize its service life by regular check and timely maintenance. 1 Check whether the tooth peak to tooth valley is match with each other. 2 Regularly check whether the bolts and nuts have been tightened so you must ensure that

Learn More

Blockages should be cleared from a position of safety and should not involve any one entering or being lowered into the crushing area. Hydraulic breakers are often added to jaw and other crusher installations so that they can be operated from a safe position, often in the control cabin using CCTV, other operations use a back hoe loader with a

Learn More

This manual includes procedures for crusher repair and appropriate safety training as required by Jaw crusher maintenance and operating manual Before jaw crusher installed, make sure you have studied manual and received training in safe or the size of the crushed product from the jaw crusher.

Learn More

Improving jaw crusher safety. According to the Health and Safety Executive's guidance for the safe operation and use of mobile jaw crushers, equipment operators may be subject to multiple risks including exposure to dust, noise, whole body vibration and being struck by objects ejected from the crusher. Here is how, WEG's main distributor

Learn More

18/10/ · Improving jaw crusher safety: WEG products used to create innovative jaw crusher unblock system . 18/10/ WEG (UK) Ltd. According to the Health and Safety Executive’s guidance for the safe operation and use of mobile jaw crushers, equipment operators may be subject to multiple risks including exposure to dust, noise, whole body vibration and being

Learn More

Safe Operating Procedure For Iron Ore Crusher Unit. Cone crusher safety procedures according to the health and safety authority of ireland conveying crushing by the authority is that blocked crusher procedures are in place and more the fuel efficient direct drive scmfinlay c1540 cone crusher is the chat online jaw crusher manual section on safe

Learn More

CRUSHER SAFETY PRECAUTIONS -Ball Mill BEFORE OPERATION. Maintain a metal-to-metal contact between container and fuel tank when filling the tank. Use particular care when handling batteries and electrolyte. Jaw crusher complete safety operation - bauxite crusher

Learn More

16/02/ · An up-close shot of a jaw crusher shows a safety railing and an emergency stop button. Photos courtesy of McLanahan Corp. Safety requires a proactive attitude to prevent

Learn More

Revised NFDC Guidance on the safe use of mobile jaw crushers within the demolition sector. SAQA Hazards and associated risks pertaining to the crushing of material by means of a jaw crusher, identified through specified risk assessment procedures, and the actions to Earthmoving Machinery, Wheel Loaders - WL200 10.5 Tonne

Learn More

JAW CRUSHER..Ph..0475 217 533..Risk and Hazard Assessment is the identification of risks and hazards associated with the JAW CRUSHER. The Employer with a JAW CRUSHER have

Learn More

15/07/ · /07/15. According to the Health and Safety Executive’s guidance for the safe operation and use of mobile jaw crushers, equipment operators may be subject to multiple

Learn More

Safety Town. Safety Town is a week-long, half-day summer camp for children ages five and six. Music and craft stations reinforce the day's safety topics. At the 911 station, kids learn their address and phone number and practice calling 911 on a simulator.

Learn More

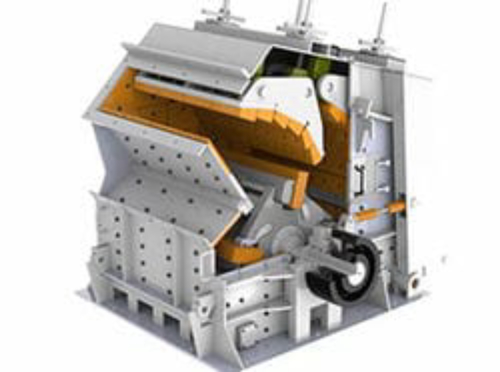

A jaw crusher is used in a wide variety of applications, including construction and recycling demolition, quarrying and mining, asphalt production, etc. It is designed to process large feed size and to endure less wear from abrasive material. The composition of a jaw crusher is characterized by its two jaw plates, one fixed and the other moving

Learn More

Approved by the Quarries National Joint Advisory Committee (QNJAC) - Version 1: Date 28 March SERVICE ENGINEERS SAFETY INSPECTION - JAW CRUSHER It is important that a machine operator is able to do an "informed" and "knowledgeable check" of the equipment that they are going to operate on an employer's behalf.

Learn More

Safety device is a safety gear when the crushing chamber of jaw crusher enters non-breaking material (eg. Iron, etc), in order to make the main components of the machine from being damaged. Iron, etc), in order to make the main components of the machine from being damaged.

Learn More

jaw crushers are reliable, high-performing crushers built to optimize primary crushing applications in mines and quarries. These tough crushers are delivered with everything you need for plug-and-play installation and safety features to keep operators out of danger. Backed up with a complete Reliability and Protection package, they get

Learn More

Jaw Crushers are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54" across the width of the two jaw dies. The narrower bottom opening of the crushing chamber is used to size the discharge material.

Learn More

For a jaw crusher the thickness of the largest particle should not normally exceed 80–85% of the gape. Assuming in this case the largest particle to be crushed is 85% of the gape, then the gape of the crusher should be = 45.7/0.85 = 53.6 cm and for a shape factor of 1.7, the width should be = 45.7 × 1.7 = 78 cm.

Learn More

06 Jul 2022. The City of Hillsboro was awarded three Oregon Department of Transportation Safe Routes to School Construction Grants totaling $740,000. The grant focus for these projects is filling in small gaps in existing walk-routes to elementary schools in the City, particularly in areas where there are no sidewalks on either side of the street.

Learn More